These Are the Main Semi Truck Transmission Types

As you may know, a transmission is what ultimately powers your truck. By using your truck’s gearbox, you’re able to either speed up or slow down. Today, we’ll go over the main semi truck transmission types.

In this article, we’ll go over the two main types of manual transmissions. That way, you can get a better picture of the gearbox types for trucks. Additionally, we’ll talk about automatic and AMT transmissions.

So, keep on reading to learn more.

Two Types of Transmissions: Synchronized and Unsynchronized

For all types of vehicles, there are two main transmissions for manual gearboxes: synchronized and unsynchronized.

Synchronized gearboxes make sure that the gears rotate and mesh, as well as locking the shaft. This allows drivers to lock the gears without any problem. Also, these transmissions help avoid double clutching.

Unsynchronized transmissions, on the other hand, are the older model of manual gearboxes. Usually, these transmissions tend to need more effort from the driver. This is because the driver needs to time the shifting of the gears. That way, the gears would rotate at the same speed.

Although unsynchronized gearboxes tend to require more endeavor from the drivers, they are less susceptible to breakdowns. Not only that but also these transmissions tend to have a much faster shifting compared to synchronized gearboxes.

Semi Truck Transmission Types: Manual, Automatic, & AMT

When thinking about semi truck transmission types, many people only have in mind two: manual and automatic transmission. However, there’s a third type of transmission: automated manual transmission.

Additionally, manual transmissions can be divided into three: splitter, range, and range splitter.

Manual Transmission

First, we have a manual transmission for semi-trucks. Being among the most traditional options out there, manual transmissions are among the most affordable transmissions. This is because they aren’t as new as their automatic counterparts.

Manual gearboxes for semi-trucks and light trucks usually consist of 6 gears and an unsynchronized transmission. Also, as we stated before in this article, manual transmissions divide into three:

- Range

- Splitter

- Range-splitter

Additionally, these types of manual gearboxes tend to be for heavy trucks that need more than six gears. Let’s take a look at each of these:

Range Gearboxes

Range transmissions usually have an H-shaped pattern. Usually, this gearbox has a high-low gear split. This split allows drivers to use the same gears shift position for both the higher mode and the lower mode.

Let’s give you an example of this. Picture that your truck has an 8-speed range transmission. The shift pattern will only have half of the range transmissions, in other words, 4 gears. As you can imagine, the first four are accessed through the low-range setting.

From the fifth gear to the eighth gear, you’ll need to use the high-range setting. By using the high range, you’ll reuse the same positions that were used for the first five gears. The first gear position becomes the fifth gear position, and so forth.

For a much better picture, take a look at the image below.

It’s a visual representation of an Eaton fuller transmission. Here you can see how the first gear position is the same for the sixth position. Also, when changing settings, you’ll need FIRST to preselect the range setting.

Splitter Gearboxes

Splitter transmissions, like range transmissions, consist of an H-pattern as well. However, splitter gearboxes tend to be gear positions that are split into two due to its high-low division.

Let’s bring back the example used for range gearboxes. Imagine that your truck has an 8-speed splitter gearbox. You’ll always have a gearbox with four positions.

With this type of transmission, instead of using the first gear position as the sixth gear position, you’ll use it as the second gear position.

In other words, the first gear will be in the first low split position, while the second gear will be in the first high split position. This will continue until you reach the final gear.

Below, you can find a diagram that shows you how shifting between gears for a splitter transmission is:

Range-Splitter Gearboxes

Lastly, we have range-splitter transmissions. As the name suggests, these are a combination of ranger and splitter gearboxes. By having a combination of the two, there’s a greater gear ratio.

A range-splitter gearbox grants truck drivers much more flexibility, as well as a broader range and selection of movements.

Below, you’ll see an 18-speed transmission shift pattern diagram for you to get a much better picture:

Automatic Semi Truck Transmission

Automatic gearboxes are among the newest options available for semi truck transmission types. Instead of featuring the good-old three-pedal manual transmissions, an automatic gearbox only features two pedals. There’s no need for three since there’s no clutch pedal.

Semi-truck automatic transmissions often include the modern planetary automatic gearboxes and dual-clutch transmissions. We’ll explain the difference between these two below:

Planetary Automatic Transmission

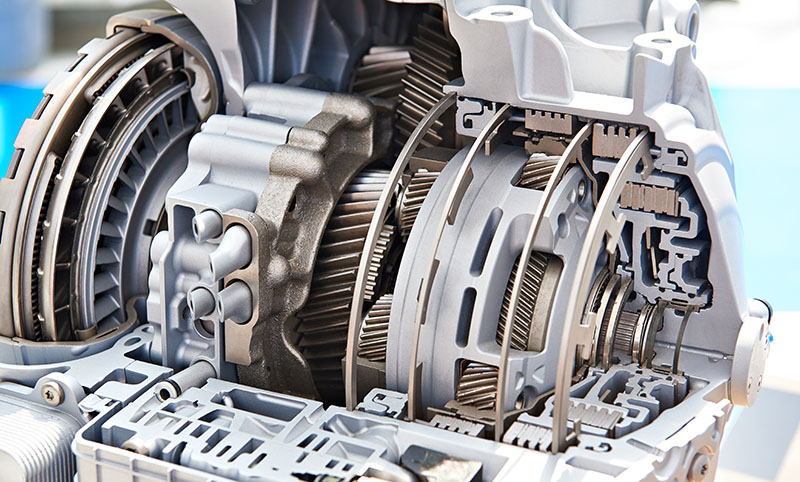

Usually, automatic planetary gearboxes are the most common type of automatic gearbox. This transmission grants a smooth coupling between the driveline and the engine. Also, it grants torque multiplication when starting.

Dual-Clutch Transmission (DCTs)

Dual-clutch gearboxes share a very much alike structure to their manual counterparts. However, DCTs have automatic shifting. Not only that, but they use two clutches and two coaxial input shafts.

You can think of DCTs as a manual gearbox, with the difference that it’s computer-controlled. While one clutch controls the odd gears, the other clutch controls the even gears.

Automated Manual Transmission

Lastly, we have automated-manual transmissions, also known as AMTs.

This type of gearbox combines the mechanism between a manual transmission and an automatic one. In essence, AMT transmissions are manual transitions that have either electro-hydraulic or electromechanical actuators. These actuators are what make it automatic since they automate the gear selection and clutch.

AMTs help you with your fuel economy by a lot. Believe it or not, when drivers shift incorrectly, they can affect your torque converters. In other words, this ends up burning much more fuel than what’s needed.

Also, an AMT gearbox is much easier to learn with than a manual one, helping you out with your driver recruitment.